Certification

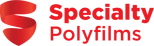

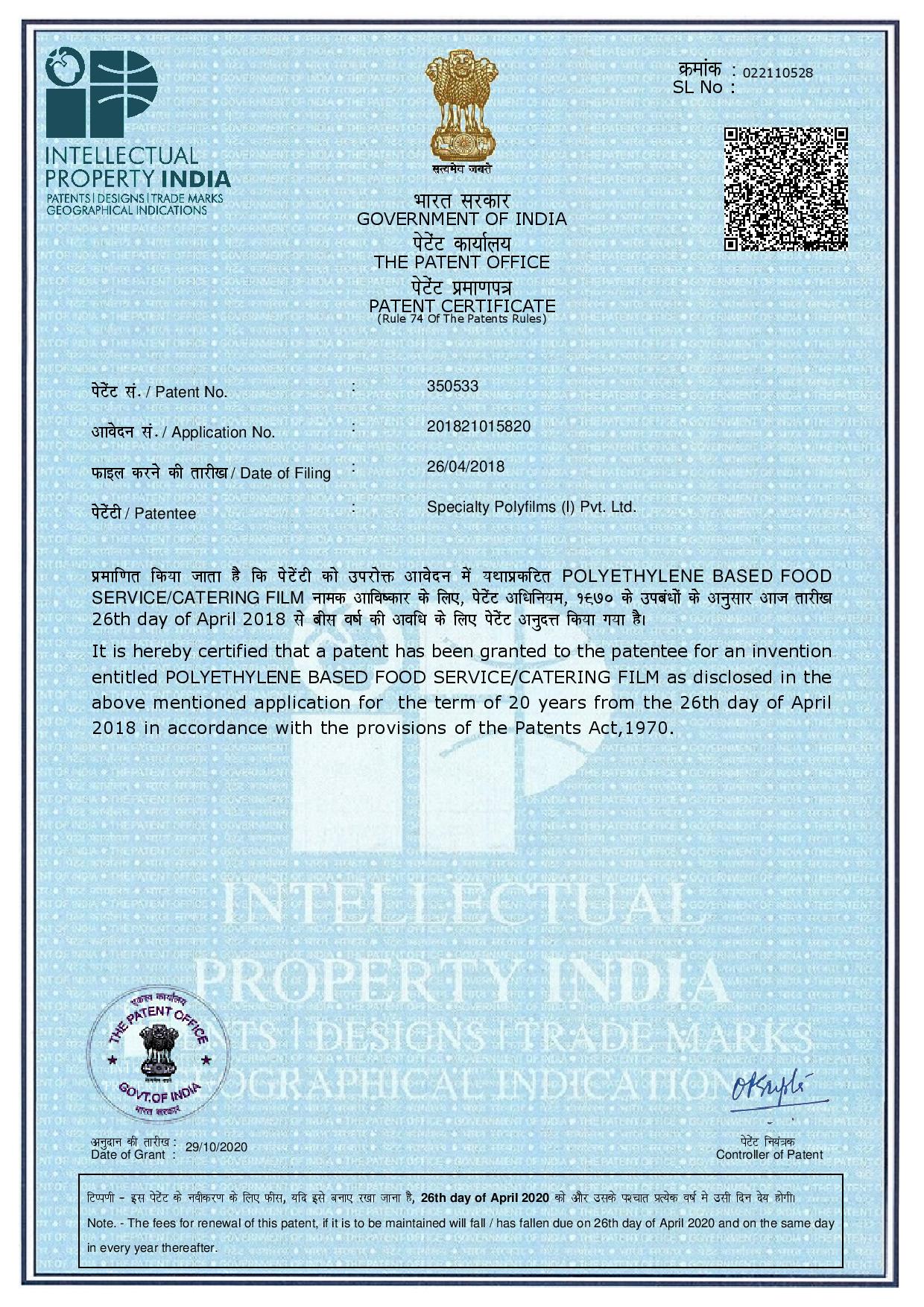

We are a BRCGS Packaging Materials, SA 8000 & ISO 9001 certified company. Forvara® & WRAPit® fully comply with food contact regulations of the US, EU and other countries.

We are a SEDEX registered organisation.

We strictly adhere to international standards of process control, quality conformance, workplace safety, employee welfare and continual improvement in quality management systems.